Understanding the Woven Garment Production Process: A Guide for Fashion Brands

Understanding the Woven Garment Production Process: A Guide for Fashion Brands

Partnering with a reliable manufacturer is crucial for bringing your fashion designs to life. For brands working with woven fabrics (such as Cotton twill, Oxford, Corduroy), understanding the core production stages ensures a smooth partnership and a high-quality final product.

At Willow Garment, we believe in transparency and precision at every step. Here is a breakdown of our essential woven garment production process.

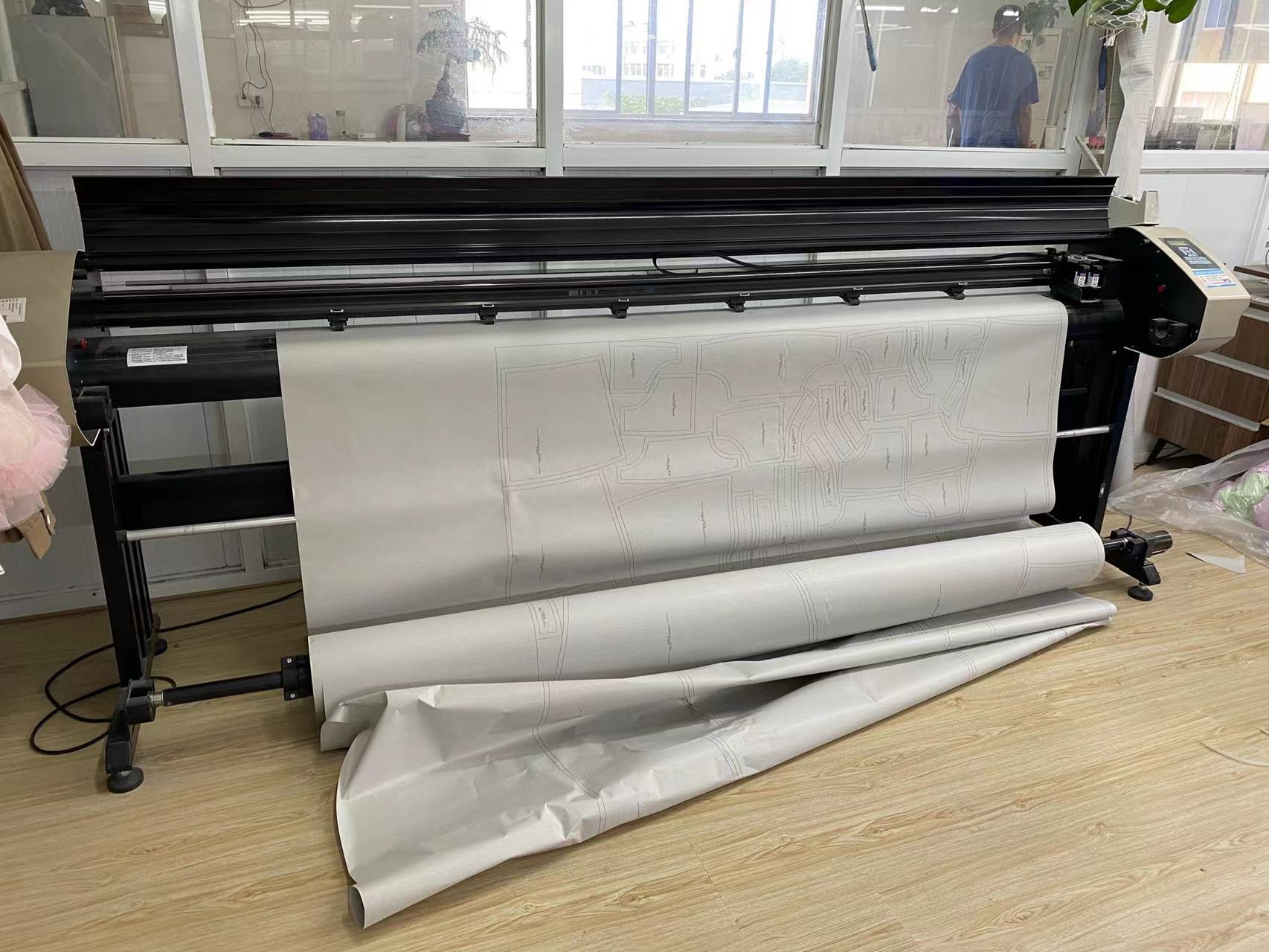

1. Pattern Making: The Blueprint of Your Design

The journey begins with transforming your design sketch into a technical blueprint.

- What it is: Pattern making involves creating a set of flat, template pieces that represent the different parts of your garment (e.g., front, back, sleeves, collar).

- Our Process: Our technical team uses your tech pack and specifications to draft precise initial patterns. We account for design ease, seam allowances, and fabric shrinkage. These first patterns are typically made from cardstock and are used to create a sample garment.

- Why it Matters:Precision at this stage is non-negotiable. A perfect pattern is the foundation for perfect fit, consistency, and efficient fabric use during cutting.

2. Fabric Cutting: Precision Meets Preparation

Once the pattern is approved and the fabric is sourced and inspected, we move to the cutting room. This is where the fabric is transformed from a roll into garment components.

- What it is: The process of laying fabric in multiple plies (layers) and cutting through them using the paper patterns as a guide.

- Our Process: We employ a combination of manual spreading for smaller runs and computerized spreading for large-scale orders to ensure fabric stability and grain alignment. Cutting is then performed using high-precision straight knives, round knives, or fully automated computerized cutting systems for absolute accuracy and speed.

- Why it Matters: Meticulous cutting ensures that every piece of your garment is identical, maintains the fabric's integrity, and minimizes waste, directly impacting your cost and quality.

3. Sewing & Assembly: Where the Garment Takes Shape

This is the stage where the cut components are assembled into a finished garment.

- What it is: The sewing department is the heart of the factory, where skilled operators stitch the pieces together using specialized industrial machines.

- Our Process: We organize production using an assembly line system, where each operator specializes in a specific task (e.g., shoulder seams, side seams, collar attachment, cuff setting). This method maximizes efficiency and quality control. We utilize a range of machinery, including single-needle lockstitch, overlock for seam finishing, and bartack machines for reinforcing stress points.

- Why it Matters: Expert sewing ensures strong, consistent, and clean seams. Our quality control team conducts in-line checks throughout this stage to identify and rectify any issues immediately, preventing defects from moving down the line.

4. Pressing & Finishing: The Final Touch of Professionalism

A garment isn't complete until it has been properly pressed and finished. This step elevates the product from homemade to professionally manufactured.

- What it is: Pressing involves using industrial irons and steam to shape the garment and create crisp seams. Finishing includes adding final labels, trimming loose threads, and conducting a final inspection.

- Our Process: We use a variety of pressing equipment, from steam irons and buck presses for flat parts to specialized mannequins (toppers) for blazers and dresses. This ensures the garment achieves its intended silhouette. After pressing, each piece undergoes a rigorous final quality check for any stitching, fabric, or finishing flaws.

- Why it Matters: Proper pressing gives a garment its polished, retail-ready appearance. It sets the shape and ensures it looks perfect for your customer. The final inspection is our last line of defense, guaranteeing that only flawless products are packaged for shipment.

5. Packaging: Ready for Market

The final step is preparing your garments for transit and retail.

- What it is: Garments are folded, tagged, and packed according to your specific instructions.

- Our Process: We offer a wide range of packaging options, from simple polybagging to custom hangtags, tissue paper, and retail-ready cartons. We ensure the packaging protects the garment and aligns with your brand image.

- Why it Matters: Thoughtful packaging not only protects your investment during shipping but also enhances the unboxing experience for the end-consumer, reinforcing your brand's value.

Partner with a Manufacturer You Can Trust

The complexity of woven garment production demands expertise at every stage. At Willow Garment, we combine skilled craftsmanship with stringent quality control to deliver collections that meet your exact specifications, on time and within budget.

Ready to discuss your next production project? [Contact us today] for a consultation.